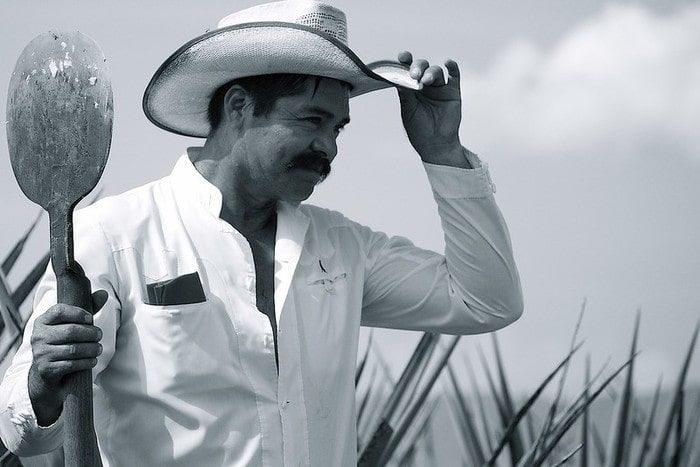

Tequila Production Process from Agave in Mexico

The tequila production process begins in the agave fields when the agaves are selected to be harvested and taken to the factories for processing. Later in the factory, the following processes take place: grinding, cooking, fermentation, distillation, maturation, filtration, dilution, and bottling.