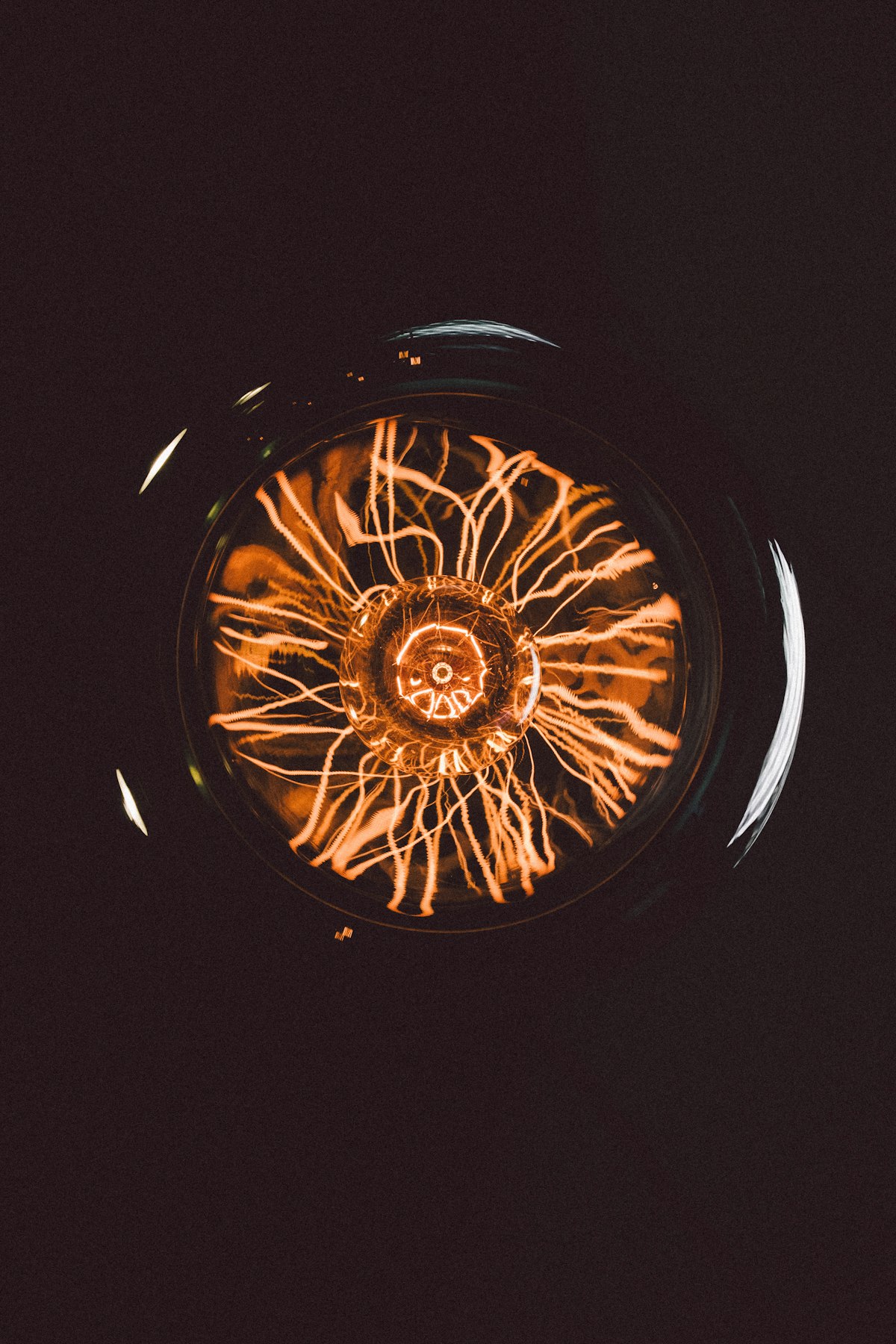

Electroceramics: improved materials for fuel cells generate electricity

With the use of nanotechnology, researchers can make more efficient inputs to elaborate essential parts of solid oxide fuel cells, generate electricity by combining hydrogen and oxygen, and promote the use of renewable energies.

With the use of nanotechnology, a group of researchers and students from the Materials Research Institute of the UNAM managed to make more efficient inputs to make essential parts of solid oxide fuel cells, to generate electricity by combining hydrogen and oxygen, and promote the use of renewable energies.

The cells are electrochemical reactors that lack combustion processes. By using these elements, the result is to obtain electric energy and water vapor, instead of polluting gases that cause the greenhouse effect, such as those from burning fossil fuels, explained IIM researcher José Álvaro Chávez Carvayar in an interview.

In their research, the scientists improve the fundamental parts of these battery-like devices, which consist of two electrodes: an anode and a cathode, separated by a dense solid electrolyte.

Fuel is supplied to the anode where an oxidation reaction occurs and releases electrons to the external circuit. Meanwhile, the oxidant is supplied to the cathode, where electrons arrive from the external circuit and the reduction reaction occurs. In between the two is the solid electrolyte, an electronic insulator that allows the transport of oxygen ions between the two electrodes.

Chávez Carvayar and his collaborators researched in the laboratory the structure and properties of these three components to make them more efficient; as a result, they achieved electroceramics resistant to high temperatures, with similar coefficients of thermal expansion and porous for the anode and cathode. They also synthesized denser electrolytes with improved ionic conductivity to reduce the operating temperature of these devices.

"In general terms, ceramic materials are inorganic materials made up of ionic and covalent bonds, which give them their characteristic properties such as low ductility, low hardness, and high melting points," he explained.

While traditional ceramics are used to make tableware, refractories, and tiles, there are other high-tech ceramics with exceptional physical and chemical properties. Among their specific applications are heat-resistant products, cermets (a combination of metals and ceramics), automotive parts, as well as electrical and electronic components, such as those used in various computer devices and cell phones.

As for electroceramics, it is possible to indicate that they present transport (or conductive) properties in a wide range of values since they go from semiconducting insulators to superconductors. In addition, if they are nanostructured, they will generally have superior properties. It is these materials that are used to make the basic parts of solid oxide fuel cells.

To obtain the materials that will make up the anode, cathode, and electrolyte, specialists use various synthesis methods, including the Pechini process (a variant of the sol-gel method), combustion, ultrasonic pyrolytic spray, combustion, and sound synthesis, among others.

Subsequently, different processes and thermal treatments are applied to give them the conductivity, hardness, and porosity appropriate to each component of the cell. Currently, Chávez Carvayar and his team have developed 80 percent of a solid oxide fuel mono cell in the laboratory and when it is finished, they will start the patent process.